What makes a belt better than a chain and vice versa? The answer is nothing. Belts are no better than… Read more »

Tag: Food Processing Conveyors

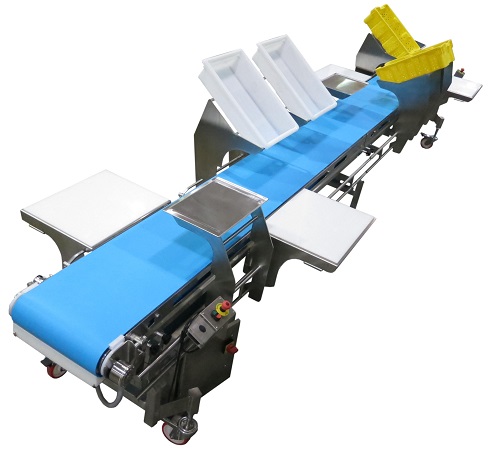

Tray Filling Conveyor with Retractable Tail

Recently, we had a customer looking to improve the efficiency of their food production line. The product was coming… Read more »

Improving a Ready-to-Eat Assembly

Recently, one of our customers requested a versatile assembly conveyor for its popular ready-to-eat sandwich products. To meet their needs,… Read more »

Dorner Application Story – Confectionery Maintenance

-Problem Belt problems on the conveyors at Gertrude Hawk Chocolates were turning a sweet job into a bitter experience. The belts… Read more »